Experience the world's first intelligent 3D bioprinting system.

From Research to Scalable Production:

Unlock consistent results with automated process supervision.

Setting a new standard in bioprinting with process intelligence.

3D Bioprinting struggles with inconsistent results due to variability in materials, environmental parameters and manual adjustments. This makes research difficult and non-reproducible.

biomotion solves this problem with process intelligence.

Our 3D biofabrication system learns the printability of your bioink and monitors the bioprinting process in real-time to deliver excellent shape fidelity.

This ensures consistent results every time and provides non-destructive data for quality management.

Internal Process Supervision

Continuous monitoring and automated corrections guarantee consistent results for every batch, reducing the need for expert intervention.

Validated Processes

Extensive library of proven geometries and bioinks help you go from 2D cell culture to relevant 3D biomimetic systems.

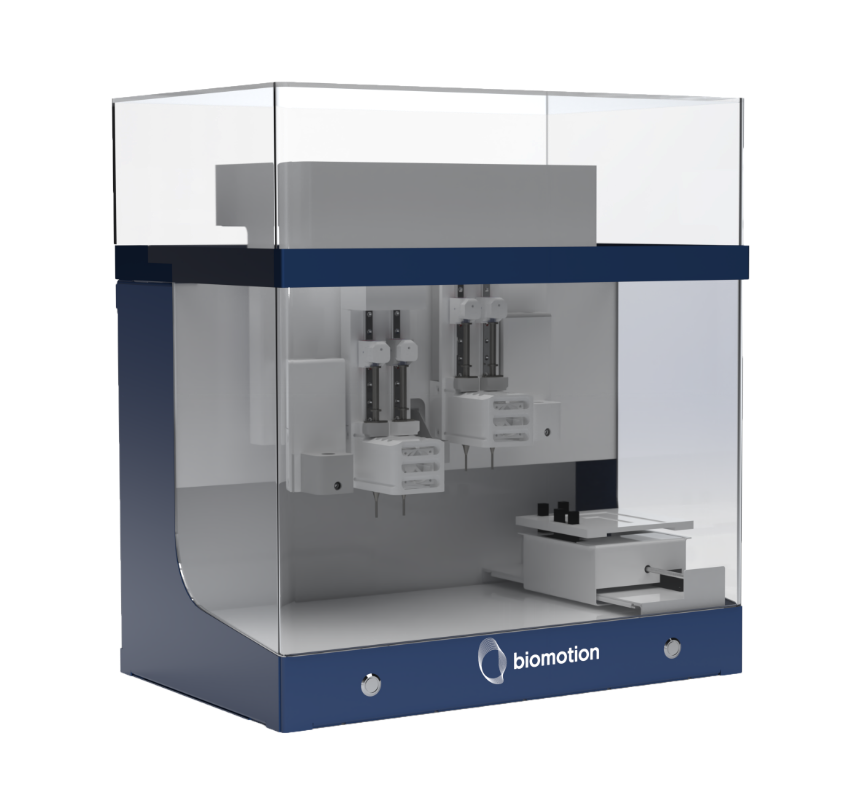

Powerful 3D Bioprinter

A robust bioprinting system designed with uncompromised build quality. The ExplorerONE.

ExplorerONE

Engineered for Consistency.

Printer Hood

(airflow hood and closed hood)

Contactless Printhead &

Surface probing

Exchangeable Printheads

Exchangeable Printing

Surfaces

User-friendly

Print within minutes regardless of prior experience

Adaptable

Leverage a wide range of printheads and printing modes to realize your ideas

Open

Customize the ExplorerONE with your ideas to meet your future research needs

Quality Assured Bioprinters

Where Research Becomes a Product

Standardize your production of tissues and scaffolds using our bioprinters with a built-in quality assurance system.

Consistency in production is essential – when expanding operations, your focus should be on the complexity of biology, not on monitoring your bioprinter.

Biomotion creates machine learning co-pilots tailored for advanced bioprinting, finely adjusting your bioink printing parameters and providing real-time production monitoring. This innovative technology can substantially cut down on your number of printing runs, thus minimizing wastage of cells, biomaterials, and time.

Our innovative system doesn’t just monitor; it actively corrects on the fly, ensuring a standardized bioprinting process that operates reliably and reproducibly and minimizes your dependency on a single expert operator.

Process monitoring

Real-time process data acquisition in non-destructive and sterile way

repeatable outcome

Automatically corrects your bioprinting process, when a deviation is detected to receive comparable results with each print

Operator independent

Reduce your dependency on single expert workers with our hands-off approach

Explore the possibilities of Bioprinting

ADVANCED HUMAN IN VITRO MODELS

Create physiologically-valid models for drug discovery with advanced bioprinting. Mimic multiple cell types and materials, from skin tissue for personalized medicine to 3D cancer models for drug testing.

ORGAN-ON-A-CHIP MODELS

Craft perfusion-ready tissue systems: blend biological and non-biological materials for dynamic cellular interfaces. Create micro-physiological device, for high-throughput drug metabolism and toxicity studies, such as liver tubules-on-a-chip.

DRUG-ELUTING PHARMACEUTICALS

Craft personalized medicine with controlled release and custom designs. Achieve time-dependent profiles and location-controlled delivery. Explore 4D bioprinting with stimuli-responsive structures.

Testimonials

Jeremy Dinoro, PhD

Researcher, University of Wollongong

I am absolutely thrilled with my experience using this 3D bioprinting system! Its versatility has been a game-changer for my research projects, effortlessly adapting to meet the changing requirements. The user-friendly software made it a breeze to onboard new students, accelerating their understanding and proficiency in bioprinting. I highly recommend this system to anyone seeking a reliable and efficient solution for their bioprinting needs.

Paula Vena, PhD

Post-doctoral researcher, TU Eindhoven

The fact that was able to switch use between the different printheads and printing modes, that come along the BIOMOTION bioprinting system, helped my research project progress immensely. A very big thank you to Gregor and Diego, who were also there to support me along the way. From a peer researcher to another, trust them, they know their bioprinting business well and their product is ready to fully cover your research needs with a ground-breaking flexibility!

A. Prof. Miguel Dias Castilho

Biomedical Engineering, TU Eindhoven

We were delighted to test and witness the adaptability of the bioprinter and its different components in action. The product, and especially its innovative and open expansion kit, offer a unique opportunity to any researcher to explore and surpass any research boundaries they come across. This is, without a doubt, a highly versatile and indispensable product that we know our research will benefit from, both in the near as well as the long-term future.